ABOUT US

The welding experts

Ebflow is the latest in a long line of electron beam welding innovations from Cambridge Vacuum Engineering (CVE).

Founded in the 1950s, CVE is a global leader in the development and manufacture of power beam welding systems – with more than 1300 systems installed worldwide.

A global partner

CVE has a track record for building some of the world’s most powerful electron beam (EB) welding systems.

With 95% of its equipment exported from the UK, the business has sites in Cambridge, UK; Beijing, China; and Springfield, Massachusetts. From these locations, CVE’s experts manufacture systems, provide advice on the selection and implementation of power beam welding technologies, and offer legacy sales and technical service support.

- A wealth of experience

- Global reach

- Award-winning technology

- Industry leading service and support

- Bespoke consultancy and solutions.

Team

The Ebflow team

Chris Punshon

Director of Ebflow Research Development & Applications

Phil Konradt

Ebflow Project Manager

Paul Plumb

Engineering Director

Greg Wallace

Engineering Manager

Chris Clarke

Welding Technician

Nick Edge

Consultant

Bob Nicolson

Managing Director

Roger Smith

Ebflow Specialist Fitter

Luke Sansby

Ebflow Sales & Marketing Director

Creating Ebflow

Ebflow is the result of years of research and development by the team at CVE. Created at the turn of the millennium, Ebflow was engineered with several clear objectives in mind. The team’s goals were to:

- Create a transportable, power beam welding machine that could quickly and efficiently deliver continuously repeatable and accurate high-quality welds, with minimal localised welding induced residual stresses

- Develop a solution that could deliver welds that are metallurgically indistinguishable from the parent material, whilst also having minimal distortion.

By taking electron beam welding outside of the vacuum chamber and using a local vacuum-based solution, CVE has created a unique system that offers unrivalled flexibility for welding projects, wherever you are in the world, whatever the scale of welding challenge.

What our customers say

With monopile type foundations accounting for over 90% of foundations used in UK projects, Ebflow could realise significant cost savings on future projects. These substantial savings will not only benefit the UK offshore engineering industry, but could be passed on to UK energy consumers.

Olly Cass

SSE Renewables Project Director

Dogger Bank

Overview

A potted history of CVE

1950s: CVE’s history began in the late 1950s in Cambridge, UK, with the founding of Torvac: a company specialising in the manufacture of electron beam welders and vacuum furnaces.

1960s: In the 1960s, a breakaway group formed Wentgate Engineers. For many years, the two companies traded in competition.

1980s: Torvac and Wentgate Engineers were both acquired by Thermal Scientific, under their new TI Group ownership. The companies reconciled, moved to a new site, and began trading under a new name – Cambridge Vacuum Engineering (CVE).

2000s: In 2001, Aquasium Technology Ltd became the new owner of CVE. Taking the business from strength to strength, Aquasium added revolutionary technologies such as Ebflow and Ebflow Light, as well as laser welding systems.

In 2007, CVE merged with WDI in the USA creating a new subsidiary CVE Inc., based in Massachusetts.

2020s: In 2020, CVE opened an office in China to meet demand for its products in the region and provide first-class, local customer support.

FAQs

What is electron beam welding?

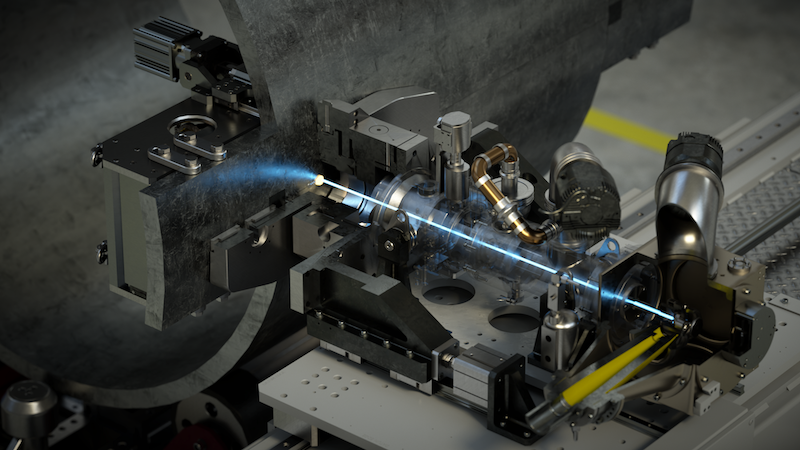

Electron beam welding is a high-precision welding process that uses a focused beam of high-velocity electrons to melt and join materials, often in a vacuum to prevent contamination. This technique allows for deep weld penetration with minimal distortion, making it ideal for applications requiring high-quality welds in aerospace, power generation, shipbuilding and civil engineering projects.

How is Ebflow different?

Ebflow takes electron beam welding outside of the vacuum chamber. Employing a series of seals to create a local vacuum around just the area being welded, Ebflow delivers greater flexibility in how and where electron beam welding can be used and is compliant with appropriate industry codes and standards set by regulatory bodies such as DNV and ASME.

Is implementing Ebflow expensive?

Electron beam welding equipment is more expensive than standard welding – but the time and cost savings on offer are monumental. Ebflow can help companies streamline processes and reduce the duration of welding – enhancing productivity and enabling resources to be allocated more efficiently. Using Ebflow, cost savings can be realised through reduced labor expenses, lower consumable costs and material waste, and decreased operational downtime. Additionally, the improved accuracy and consistency of the welds leads to higher quality outcomes and fewer errors that require costly corrections. The cumulative effect of these advantages boosts profitability – giving companies a competitive edge as they look to deliver products and services more quickly and at a lower cost to their customers.